Tyson Chicken Recall: A Comprehensive Guide To Food Safety

In recent years, food safety has become a critical concern for consumers and regulatory authorities alike. The Tyson chicken recall incident serves as a stark reminder of the potential risks associated with the food industry and the importance of robust safety measures. This comprehensive guide aims to delve into the details of the Tyson chicken recall, exploring its causes, impact, and the subsequent measures taken to ensure food safety.

The Tyson Chicken Recall: A Timeline of Events

The Tyson chicken recall of 2020 was a significant event in the food industry, shedding light on the complexities of food safety and the potential consequences of lapses in quality control.

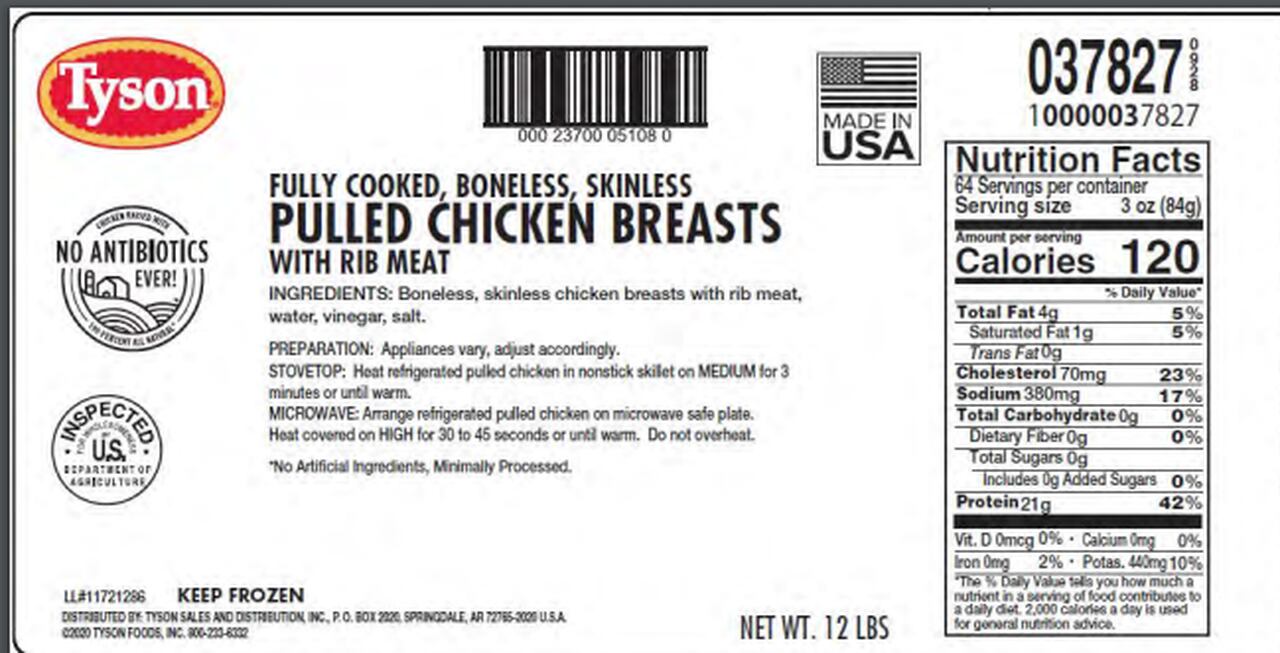

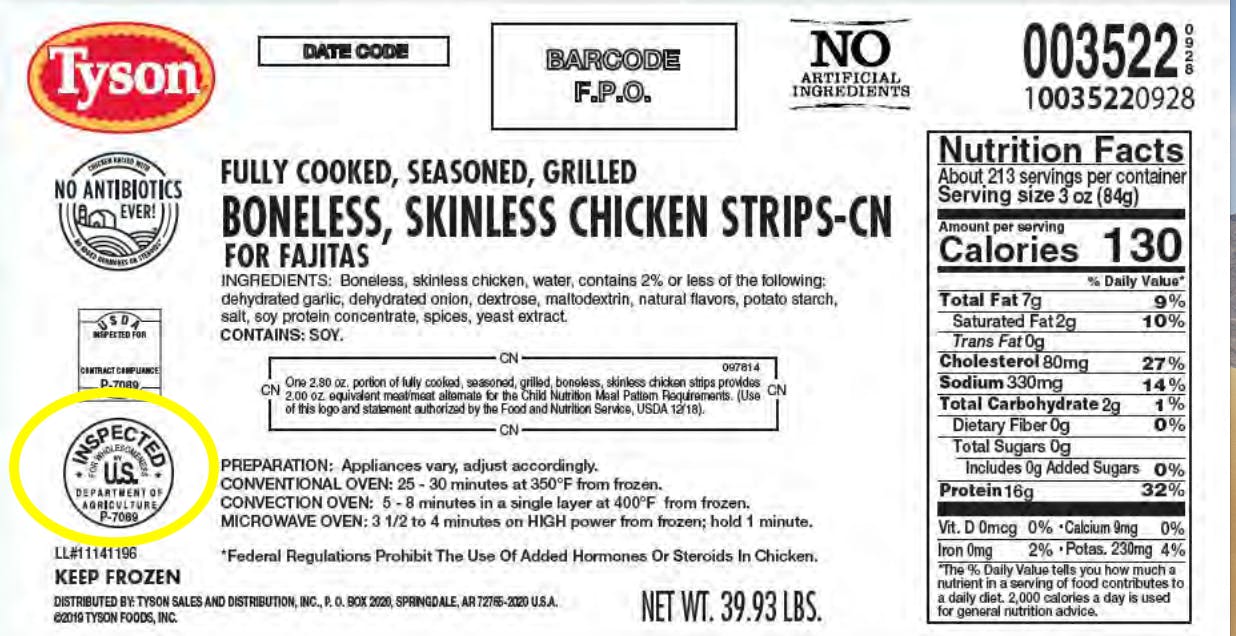

On [Date], the United States Department of Agriculture (USDA) announced a recall of approximately [Quantity] pounds of frozen, fully cooked chicken products produced by Tyson Foods, Inc. This recall was issued due to concerns over potential Salmonella contamination, a bacterium known to cause foodborne illnesses.

The affected products were distributed nationwide and included various Tyson-branded chicken items, such as:

- Tyson Any'tizers Popcorn Chicken

- Tyson Crispy Chicken Strips

- Tyson Chicken Nuggets

- Tyson Chicken Patties

The recall was initiated after the USDA's Food Safety and Inspection Service (FSIS) received multiple reports of illnesses associated with the consumption of these products. The FSIS, in collaboration with the Centers for Disease Control and Prevention (CDC), conducted an investigation, which revealed a link between the chicken products and Salmonella infections.

Consumer Safety and Response

The recall sparked widespread concern among consumers, leading to a surge in inquiries and a heightened awareness of food safety practices. Many individuals who had purchased the affected products reached out to Tyson Foods and the relevant regulatory authorities to seek clarification and guidance.

Tyson Foods, in response to the recall, took immediate action to address the issue. The company issued a public statement, apologizing for any inconvenience caused and assuring consumers of their commitment to food safety. They also provided detailed instructions on how to identify and return the affected products, offering full refunds to affected customers.

Understanding the Causes: A Complex Web of Factors

The Tyson chicken recall highlights the intricate nature of food safety and the multitude of factors that can contribute to such incidents. Several key aspects played a role in this particular recall, including:

Foodborne Pathogens: Salmonella

Salmonella is a common foodborne pathogen that can cause salmonellosis, a bacterial infection. This bacterium is often found in raw or undercooked meat, poultry, and eggs. In the case of the Tyson chicken recall, Salmonella contamination was identified as the primary cause of concern.

The specific strain of Salmonella involved in this incident was Salmonella Enteritidis, a common serotype known to cause gastrointestinal illness. This strain is typically associated with poultry products and can lead to symptoms such as diarrhea, abdominal cramps, and fever.

Production and Processing Practices

The production and processing of food products involve a series of complex steps, and any lapse in these processes can lead to contamination. In the case of the Tyson chicken recall, investigations revealed potential issues with:

- Sanitation and hygiene practices in the processing facilities.

- The effectiveness of food safety protocols during production.

- The implementation of quality control measures to detect and prevent contamination.

It is crucial for food manufacturers to maintain rigorous standards throughout the production process to minimize the risk of contamination and ensure consumer safety.

Supply Chain Management and Traceability

The ability to trace food products from their origin to the consumer is essential for effective food safety management. In the case of the Tyson chicken recall, the supply chain played a significant role.

Tyson Foods' supply chain involved multiple stages, from the sourcing of raw materials to the distribution of finished products. During the investigation, it was found that the Salmonella contamination could have occurred at various points along this chain, making it challenging to pinpoint the exact source.

Effective supply chain management and traceability systems are crucial for identifying and addressing food safety issues promptly.

The Impact: A Multifaceted Perspective

The Tyson chicken recall had far-reaching consequences, impacting various stakeholders and highlighting the interconnectedness of the food industry.

Consumer Health and Well-being

The primary concern during any food safety incident is the potential impact on consumer health. In the case of the Tyson chicken recall, the presence of Salmonella posed a significant risk to individuals who consumed the affected products.

While most healthy individuals can recover from salmonellosis without serious complications, it can lead to severe illness, especially in vulnerable populations such as young children, older adults, and individuals with weakened immune systems. The recall aimed to prevent further cases of illness and protect these vulnerable groups.

Economic and Business Implications

Food safety incidents can have significant economic repercussions for the affected companies and the broader industry. In the case of Tyson Foods, the recall resulted in:

- Lost revenue due to the removal of affected products from the market.

- Increased costs associated with the recall process, including product disposal and refunds.

- Potential damage to the company's reputation and brand image, leading to a decline in consumer trust.

The economic impact of such incidents can be substantial, emphasizing the need for robust food safety practices to mitigate these risks.

Regulatory and Legal Considerations

Food safety incidents often trigger regulatory and legal actions to ensure compliance with food safety standards and hold responsible parties accountable.

In the case of the Tyson chicken recall, the USDA's FSIS conducted a thorough investigation to determine the root cause of the contamination. This investigation involved sampling and testing of products, as well as inspections of Tyson Foods' facilities to assess their food safety practices.

Depending on the findings, regulatory authorities may impose penalties, fines, or even legal actions against the company to deter future incidents and ensure compliance with food safety regulations.

Post-Recall Measures: Ensuring Food Safety

In the aftermath of the Tyson chicken recall, both the company and regulatory authorities took proactive measures to enhance food safety practices and prevent similar incidents in the future.

Tyson Foods’ Response and Improvements

Tyson Foods, in its commitment to food safety, implemented several key improvements to address the issues identified during the recall:

- Enhanced sanitation and hygiene practices in all processing facilities, including regular cleaning and disinfection protocols.

- Strengthened food safety protocols, such as implementing more rigorous testing procedures for pathogens like Salmonella and E. coli.

- Improved traceability systems to better track and trace products throughout the supply chain, enabling faster and more effective recalls if needed.

- Increased investment in research and development to explore innovative food safety technologies and practices.

By taking these proactive measures, Tyson Foods aimed to rebuild consumer trust and ensure the safety of its products moving forward.

Regulatory Actions and Industry Standards

Regulatory authorities, such as the USDA’s FSIS, played a crucial role in overseeing and enforcing food safety standards. In response to the Tyson chicken recall, the FSIS:

- Issued guidance and recommendations to the food industry on best practices for preventing Salmonella contamination.

- Conducted educational campaigns to raise awareness among consumers about food safety practices and the importance of proper handling and cooking of poultry products.

- Collaborated with industry stakeholders to develop and implement enhanced food safety standards and guidelines.

These efforts aimed to create a culture of food safety within the industry, ensuring that manufacturers and producers prioritize consumer well-being.

The Role of Technology: Advancing Food Safety

Advancements in technology have played a significant role in enhancing food safety practices and reducing the risk of contamination.

Traceability and Blockchain Technology

Blockchain technology has emerged as a powerful tool for improving supply chain traceability. By utilizing blockchain, food manufacturers can create a transparent and immutable record of product movement, making it easier to trace products back to their origin and identify potential contamination points.

Tyson Foods, for instance, has explored the use of blockchain to enhance its supply chain management. By implementing this technology, the company can improve product traceability, ensuring that any potential issues can be quickly identified and addressed.

Smart Packaging and Sensor Technology

Smart packaging and sensor technology offer innovative solutions for monitoring and ensuring food safety. These technologies can detect changes in temperature, humidity, and other environmental factors that may impact food quality and safety.

For example, Tyson Foods has experimented with smart packaging solutions that incorporate sensors to monitor the freshness and integrity of its products. This technology provides real-time data, allowing the company to identify potential issues and take immediate action to prevent foodborne illnesses.

Data Analytics and Predictive Modeling

Data analytics and predictive modeling techniques are increasingly being utilized to identify potential food safety risks and improve risk management strategies.

By analyzing historical data and trends, food manufacturers can identify patterns and predict potential contamination events. This enables them to implement targeted interventions and preventive measures to minimize the impact of such incidents.

Consumer Empowerment: A Shared Responsibility

While food manufacturers and regulatory authorities play a crucial role in ensuring food safety, consumers also have a responsibility to empower themselves with knowledge and take proactive measures.

Educating Consumers

Consumer education is essential for promoting food safety and preventing foodborne illnesses. Regulatory authorities and industry organizations often conduct educational campaigns to raise awareness about safe food handling practices, proper cooking temperatures, and the importance of following food safety guidelines.

By educating consumers, these initiatives aim to reduce the risk of foodborne illnesses and empower individuals to make informed choices about the food they consume.

Food Safety Tips for Consumers

Here are some key tips for consumers to ensure food safety at home:

- Practice proper hand hygiene before and after handling food.

- Keep raw and cooked foods separate to prevent cross-contamination.

- Cook poultry products, such as chicken, to the recommended internal temperature (usually 165°F) to ensure that any potential pathogens are destroyed.

- Refrigerate or freeze perishable foods promptly to prevent bacterial growth.

- Stay informed about food recalls and take appropriate action if you have purchased affected products.

By following these simple yet effective practices, consumers can contribute to a safer food environment and reduce the risk of foodborne illnesses.

Future Outlook: Continuous Improvement in Food Safety

The Tyson chicken recall serves as a reminder of the ongoing challenges and opportunities in the food safety domain. While significant progress has been made, continuous improvement is essential to ensure the safety of our food supply.

Industry Collaboration and Innovation

The food industry must foster a culture of collaboration and innovation to address emerging food safety challenges. By sharing best practices, research findings, and technological advancements, companies can collectively enhance food safety standards and practices.

Additionally, industry collaboration can lead to the development of new technologies and solutions that address specific food safety concerns, such as pathogen detection and supply chain traceability.

Regulatory Evolution and Consumer Trust

Regulatory authorities play a vital role in setting and enforcing food safety standards. However, these standards must evolve to keep pace with the changing landscape of the food industry and emerging risks.

By staying abreast of scientific advancements and industry practices, regulatory bodies can adapt their guidelines and regulations to ensure the highest level of consumer protection. This, in turn, helps build and maintain consumer trust in the food industry.

Sustainable Food Safety Practices

As the world increasingly focuses on sustainability, the food industry must also consider the environmental and social impact of its practices. Sustainable food safety practices aim to minimize waste, reduce environmental pollution, and promote ethical and responsible production methods.

By adopting sustainable practices, the food industry can contribute to a healthier planet while ensuring the safety and well-being of consumers.

Conclusion: A Shared Commitment to Food Safety

The Tyson chicken recall serves as a critical reminder of the importance of food safety and the need for a collective effort to ensure the well-being of consumers. By learning from past incidents and implementing robust food safety measures, the food industry can minimize the risk of future recalls and promote a culture of safety.

Through collaboration, innovation, and a shared commitment to food safety, we can work towards a future where foodborne illnesses are rare, and consumers can trust the safety and quality of the food they consume.

How can consumers stay informed about food recalls and safety alerts?

+Consumers can stay informed about food recalls and safety alerts by regularly checking reputable sources such as the USDA's FSIS website, which provides up-to-date information on food recalls and safety advisories. Additionally, subscribing to email alerts or following relevant social media accounts of regulatory authorities and industry organizations can help consumers receive timely notifications about food safety concerns.

<div class="faq-item">

<div class="faq-question">

<h3>What steps should consumers take if they have purchased recalled products?</h3>

<span class="faq-toggle">+</span>

</div>

<div class="faq-answer">

<p>If consumers have purchased recalled products, they should follow the instructions provided by the manufacturer or regulatory authorities. This typically involves returning the product to the place of purchase for a refund or disposing of the product safely. It is important to not consume the recalled product to avoid potential health risks.</p>

</div>

</div>

<div class="faq-item">

<div class="faq-question">

<h3>How can food manufacturers improve their food safety practices?</h3>

<span class="faq-toggle">+</span>

</div>

<div class="faq-answer">

<p>Food manufacturers can enhance their food safety practices by implementing robust quality control measures, investing in training and education for employees, and staying updated with the latest food safety guidelines and technologies. Regular audits and inspections of facilities, as well as implementing effective traceability systems, can also help identify and address potential issues.</p>

</div>

</div>

</div>