Type 3 Barricade: A Comprehensive Guide To Your Safety

In the realm of emergency response and public safety, the Type 3 Barricade stands as a crucial component, offering a versatile and robust solution for creating temporary road closures, traffic diversions, and secure perimeters. This comprehensive guide delves into the intricacies of the Type 3 Barricade, exploring its design, applications, and significance in ensuring safety during various operations.

Design and Specifications of the Type 3 Barricade

The Type 3 Barricade is a sturdy and portable barrier system, designed to meet the highest safety standards. It consists of several key components, each playing a vital role in its overall functionality and effectiveness.

Construction and Materials

These barricades are typically constructed using high-density polyethylene (HDPE) or similar durable materials. HDPE offers excellent impact resistance, ensuring the barricades can withstand harsh weather conditions and potential collisions. The use of UV-resistant additives further enhances their durability, making them suitable for long-term outdoor use.

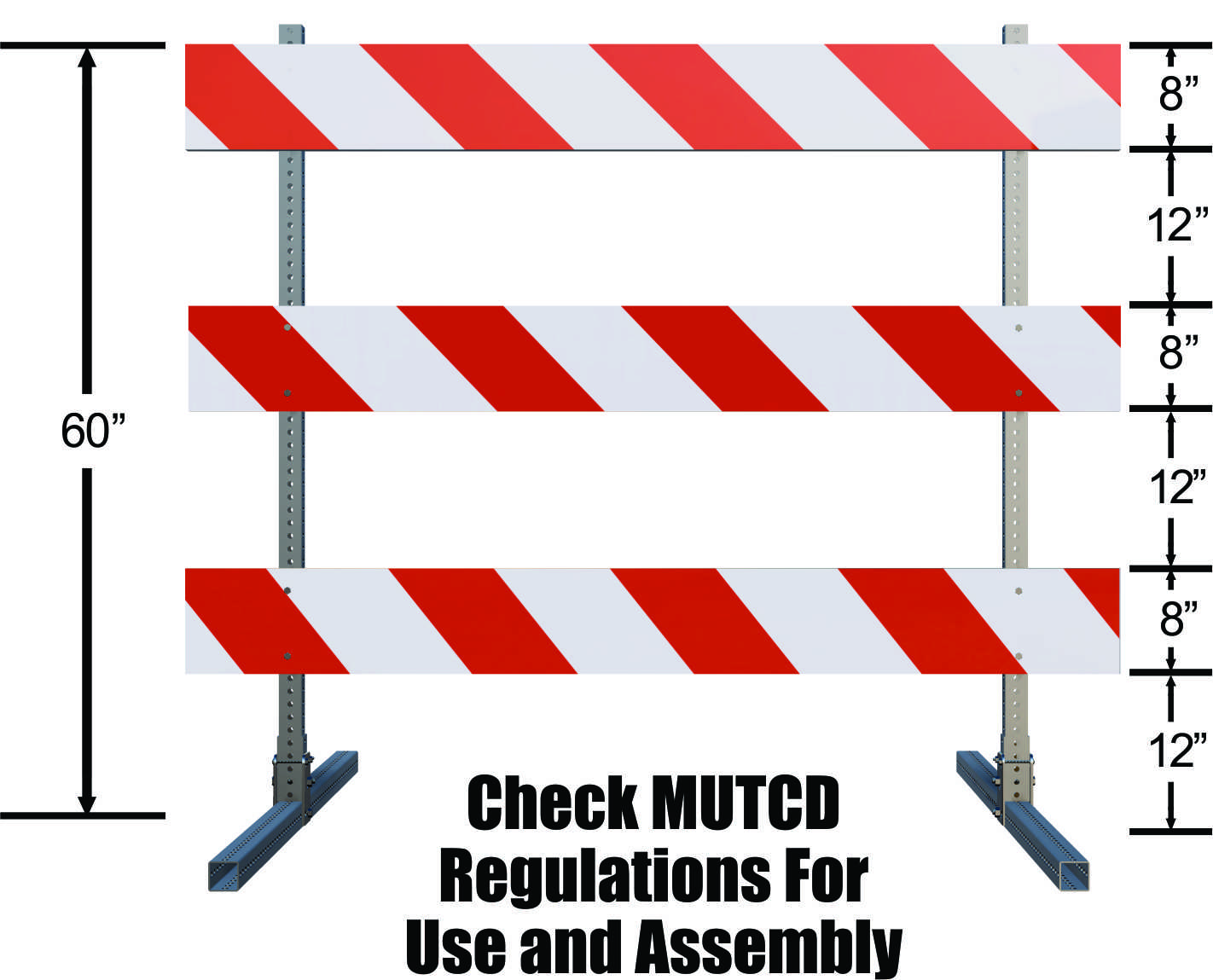

The standard dimensions of a Type 3 Barricade are 36 inches in height and 12 inches in width, providing a significant visual barrier while allowing for easy transportation and storage. Each barricade segment is connected using sturdy hinges, allowing for quick deployment and adjustment to fit various road configurations.

Weight and Stability

One of the standout features of the Type 3 Barricade is its weight. Weighing approximately 15-20 pounds, these barricades are lightweight enough to be easily maneuvered by a single person, yet heavy enough to remain stable and secure in high-wind conditions or when subjected to vehicle impact.

To enhance stability, the barricades are often designed with a weighted base or can be filled with water or sand for added ballast. This design ensures they remain in place, preventing potential hazards caused by shifting or toppling barriers.

Reflective Panels and Visibility

Safety is paramount, and the Type 3 Barricade excels in this regard. Each barricade segment is equipped with highly reflective panels, ensuring maximum visibility, especially during low-light conditions or at night. These panels are strategically placed to provide a clear indication of the barrier’s presence, guiding both drivers and pedestrians away from restricted areas.

| Barricade Feature | Description |

|---|---|

| Reflective Panels | Highly reflective material enhances visibility in low-light conditions. |

| Weight | Lightweight design for easy handling, yet stable and secure. |

| Durable Construction | HDPE construction ensures long-lasting performance and resistance to environmental factors. |

Applications and Benefits of Type 3 Barricades

The versatility of Type 3 Barricades makes them an indispensable tool across various industries and emergency response scenarios. Their effectiveness lies in their ability to adapt to different situations while providing a reliable and visible barrier.

Emergency Response and Disaster Management

In the aftermath of natural disasters or emergency situations, Type 3 Barricades play a crucial role in establishing safe zones and controlling access to affected areas. They are often used to block off roads, create diversion routes, and prevent unauthorized entry, ensuring the safety of both responders and the public.

For instance, during a hurricane evacuation, these barricades can be quickly deployed to guide traffic away from low-lying areas and towards safer routes. Their reflective panels make them highly visible, even in the dark, providing essential guidance to drivers and emergency vehicles.

Road Construction and Maintenance

The construction industry heavily relies on Type 3 Barricades to create safe work zones and protect both workers and the public. These barricades are ideal for setting up temporary road closures, lane diversions, and detour routes during road construction or maintenance projects.

By using Type 3 Barricades, construction crews can effectively manage traffic flow, minimizing disruptions and ensuring the safety of all road users. The barricades' modular design allows for easy configuration, adapting to the unique requirements of each construction site.

Special Events and Crowd Control

Organizers of large-scale events, such as concerts, festivals, and marathons, turn to Type 3 Barricades to manage crowds and create controlled access points. These barricades provide a physical barrier, preventing unauthorized entry and ensuring a smooth flow of attendees.

Additionally, they are instrumental in creating designated areas for emergency services, VIP access, and other special sections within the event venue. The reflective panels enhance visibility, making it easier for event staff and security personnel to monitor crowd movements and maintain order.

Security and Perimeter Control

Beyond emergency response and construction, Type 3 Barricades find applications in security operations. They are often used to establish temporary perimeters around high-risk areas, such as protest sites, VIP events, or active crime scenes. The sturdy construction and high visibility of these barricades make them an effective deterrent, preventing unauthorized access and ensuring the safety of personnel and the public.

Deployment and Maintenance

The effectiveness of Type 3 Barricades relies not only on their design but also on proper deployment and maintenance practices.

Training and Protocols

It is essential to provide comprehensive training to personnel responsible for deploying and managing Type 3 Barricades. This includes instruction on proper placement, alignment, and spacing to ensure the barricades are set up effectively and safely.

Standard operating procedures should be established to guide the deployment process, taking into account factors such as traffic flow, weather conditions, and the specific requirements of the situation at hand. Regular drills and simulations can further enhance the proficiency of personnel in handling these barricades.

Inspection and Maintenance

Regular inspection and maintenance are critical to ensuring the continued reliability and safety of Type 3 Barricades. This includes checking for any signs of damage, such as cracks, fading of reflective panels, or loose hinges. Any damaged barricades should be promptly repaired or replaced to maintain their integrity.

Additionally, proper storage and handling practices are essential to prolong the lifespan of these barricades. When not in use, they should be stored in a dry, secure location, protected from extreme temperatures and UV exposure. Regular cleaning and maintenance can also help prevent the buildup of dirt and debris, ensuring the barricades remain highly visible and effective.

What are the key differences between Type 1, Type 2, and Type 3 Barricades?

+Type 1 Barricades are the lightest and most portable, often used for short-term traffic control. Type 2 Barricades offer more stability and are suitable for longer-term applications. Type 3 Barricades strike a balance between weight and stability, making them versatile for a wide range of uses.

How often should Type 3 Barricades be inspected and maintained?

+Regular inspections should be conducted at least once a month, or more frequently if the barricades are exposed to harsh conditions. Maintenance tasks may include cleaning, repairing damage, and checking the integrity of reflective panels and hinges.

Can Type 3 Barricades be customized for specific applications?

+Yes, Type 3 Barricades can be customized with additional features such as signage, lighting, or specialized reflective panels to meet the unique needs of specific applications. Customization options should be discussed with manufacturers or suppliers.