Coal Bed Methane: A Comprehensive Guide To Energy Extraction

Coal Bed Methane (CBM), also known as Coal Seam Gas, is a valuable energy resource with a significant role in the global energy landscape. As concerns about climate change and the need for cleaner energy sources intensify, understanding the extraction process and potential of CBM becomes increasingly crucial. This comprehensive guide aims to delve into the intricate details of Coal Bed Methane, from its geological formation and extraction techniques to its environmental considerations and future prospects.

The Geological Formation of Coal Bed Methane

Coal Bed Methane is a natural gas that is trapped within coal seams. It forms through a complex process that begins with the accumulation of organic matter, primarily plant material, in sedimentary basins. Over millions of years, as these organic-rich sediments are buried and subjected to increasing temperature and pressure, they undergo a series of chemical and physical transformations, known as coalification.

During coalification, the organic matter transforms into different ranks of coal, from lignite (the lowest rank) to anthracite (the highest rank). As the coal matures, it releases methane, a by-product of the decomposition of organic material. This methane becomes trapped within the coal's porous structure, forming CBM reservoirs.

The presence of CBM is influenced by several geological factors, including the coal's rank, porosity, permeability, and the presence of fractures and faults. Coal seams with higher ranks generally contain more methane, as they have undergone more extensive coalification. Additionally, the permeability of the coal, which is the measure of its ability to transmit fluids, plays a crucial role in determining the accessibility of the methane.

Coal Basin Characteristics

Coal basins, also known as coalfields, are large areas where coal-bearing rocks are prevalent. These basins are typically formed by tectonic activity, such as mountain-building events or the collision of continental plates. The geological processes that create coal basins often result in the formation of structurally complex and varied terrains, which can greatly influence the distribution and accessibility of CBM resources.

For example, the San Juan Basin in the southwestern United States is one of the most prolific CBM basins in the world. It is characterized by a complex geological history, including the uplift of the Rocky Mountains and the deposition of thick coal-bearing formations. The basin's complex structure, with multiple coal seams and varying rock types, has contributed to its high CBM potential.

Extraction Techniques: Unlocking the Energy Potential

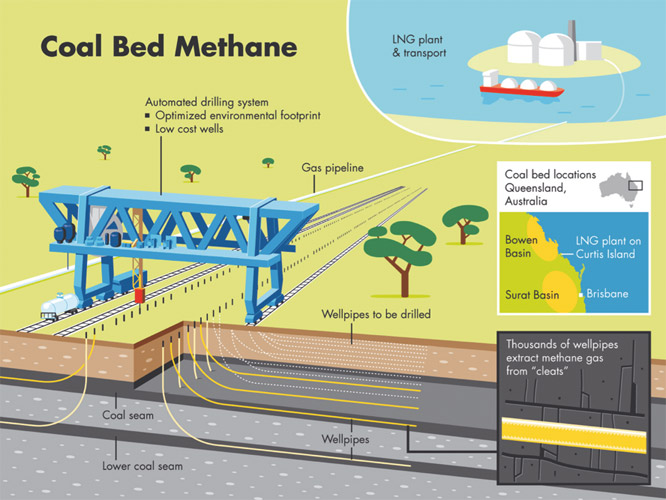

Extracting Coal Bed Methane is a complex process that requires specialized techniques and equipment. The primary method of CBM extraction is through the use of wells, which are drilled into the coal seams to access the methane-rich gas. However, the specific extraction techniques can vary depending on the geological characteristics of the coal seam and the desired production rate.

Drilling and Well Completion

The first step in CBM extraction is drilling a well into the coal seam. This is typically done using rotary drilling rigs, which use a rotating drill bit to cut through the rock. The depth of the well can vary greatly, ranging from a few hundred meters to over a kilometer, depending on the depth of the coal seam and the geological conditions.

Once the well is drilled, it undergoes a completion process to prepare it for gas production. This involves installing a casing and cementing it in place to ensure the well's structural integrity and prevent any leakage of gas or fluids. The completion process also includes the installation of production tubing and a downhole pump, if necessary, to facilitate the flow of gas to the surface.

Depressurization and Gas Production

One of the unique aspects of CBM extraction is the need to depressurize the coal seam. Unlike conventional natural gas reservoirs, CBM is typically found at relatively low pressures, often below the hydrostatic pressure of the overlying water column. This means that the coal seam is under a state of pressure, with water filling the pore spaces and applying pressure on the methane gas.

To access the methane, the water must be removed from the coal seam, a process known as dewatering. This is achieved by pumping water out of the well, which reduces the pressure and allows the methane to flow more freely. The produced water is typically treated and either reinjected into the ground or discharged under strict environmental regulations.

As the coal seam is depressurized, the methane begins to flow into the wellbore and is then transported to the surface through the production tubing. The gas is then processed to remove any impurities, such as water vapor, carbon dioxide, and other trace gases, before being delivered to the market.

Environmental Considerations: Balancing Energy Needs and Sustainability

While Coal Bed Methane offers a promising energy source, its extraction and utilization come with environmental considerations that must be carefully managed. The potential environmental impacts of CBM operations can be categorized into three main areas: water resources, land and ecosystems, and greenhouse gas emissions.

Water Resources

The dewatering process in CBM extraction can have significant impacts on local water resources. The removal of large volumes of water from the coal seam can lower the water table, potentially affecting nearby streams, wetlands, and groundwater-dependent ecosystems. Additionally, the produced water, which often contains high levels of salinity and minerals, must be carefully managed to prevent contamination of surface and groundwater sources.

To mitigate these impacts, CBM operators must implement robust water management plans. This includes monitoring water levels and quality, treating and reusing produced water where possible, and implementing proper disposal methods for any wastewater that cannot be recycled.

Land and Ecosystems

CBM development can also impact the land and surrounding ecosystems. The construction of well pads, access roads, and other infrastructure can result in habitat fragmentation and loss, particularly in sensitive ecological areas. Additionally, the clearing of vegetation and the disturbance of soil can lead to increased erosion and sedimentation in nearby water bodies.

To minimize these impacts, CBM operators should conduct thorough environmental assessments and implement best management practices. This may include restoring disturbed areas, implementing erosion control measures, and avoiding sensitive habitats and critical wildlife corridors.

Greenhouse Gas Emissions

While CBM is often touted as a cleaner-burning fossil fuel, its extraction and utilization still contribute to greenhouse gas emissions. The burning of CBM releases carbon dioxide (CO2), a potent greenhouse gas, into the atmosphere. Additionally, the process of dewatering and gas production can result in the release of methane, which is a much more potent greenhouse gas than CO2.

To address these emissions, CBM operators can employ various strategies. These include capturing and utilizing the methane gas for power generation or as a feedstock for other industrial processes, as well as implementing leak detection and repair programs to minimize fugitive emissions.

Future Prospects: The Role of Coal Bed Methane in a Transitioning Energy Landscape

As the world transitions towards a more sustainable and low-carbon energy future, the role of Coal Bed Methane is likely to evolve. While CBM is a fossil fuel, it offers several advantages over traditional coal and oil, including higher energy content, lower emissions, and the potential for more efficient and cleaner power generation.

CBM as a Transitional Fuel

In the short to medium term, CBM can play a crucial role as a transitional fuel, bridging the gap between traditional fossil fuels and renewable energy sources. Its relatively low emissions and abundance in many regions make it an attractive option for countries seeking to reduce their reliance on coal and oil while maintaining a stable and reliable energy supply.

For example, Australia, which has significant CBM resources, has embraced CBM as a key component of its energy transition strategy. The country's abundant CBM reserves, particularly in the Bowen and Surat Basins, have the potential to provide a stable and affordable energy source for both domestic use and export.

Integration with Renewable Energy Sources

In the long term, the future of CBM is likely to be closely tied to the integration with renewable energy sources. As the cost of renewable technologies, such as solar and wind power, continues to decline, the role of CBM may shift towards providing flexible and dispatchable power generation to support the intermittent nature of these renewable sources.

For instance, CBM-fired power plants can be quickly ramped up or down to meet the variable demand for electricity, complementing the output of renewable energy sources. This integration of CBM with renewable energy can help to ensure a stable and reliable energy supply, even as the world moves towards a more sustainable energy mix.

Advancements in Extraction and Utilization Technologies

The future of CBM also relies on continued advancements in extraction and utilization technologies. Research and development efforts are focused on improving the efficiency and environmental performance of CBM operations, as well as finding new applications for CBM beyond power generation.

One area of focus is the development of more efficient and environmentally friendly dewatering technologies. For example, the use of advanced membrane technologies and desalination processes can help to reduce the volume of produced water and minimize the potential for water contamination. Additionally, the exploration of enhanced gas recovery techniques, such as the use of carbon dioxide (CO2) injection, can help to increase the overall recovery of methane from coal seams.

Global Energy Demand and Market Dynamics

The future of CBM is also closely tied to global energy demand and market dynamics. As the world’s energy needs continue to grow, particularly in developing countries, the demand for reliable and affordable energy sources will remain high. In this context, CBM, with its abundant reserves and relatively low extraction costs, can play a significant role in meeting this demand.

However, the future of CBM is not without challenges. The declining cost of renewable energy technologies and the increasing focus on climate change mitigation may lead to a shift in energy policies and priorities. Additionally, the variability of CBM resources and the potential for resource depletion in some regions may pose challenges to the long-term viability of CBM as a major energy source.

What are the key environmental concerns associated with Coal Bed Methane extraction?

+The main environmental concerns associated with CBM extraction include water resource management, land and ecosystem impacts, and greenhouse gas emissions. Proper water management plans, erosion control measures, and leak detection programs are essential to mitigate these impacts.

How does Coal Bed Methane compare to other fossil fuels in terms of emissions and environmental impact?

+CBM is considered a cleaner-burning fossil fuel compared to coal and oil. It has lower emissions of carbon dioxide (CO2) and other pollutants when burned. However, the extraction process can result in the release of methane, a potent greenhouse gas, if not properly managed.

What are the potential applications of Coal Bed Methane beyond power generation?

+CBM can be used as a feedstock for various industrial processes, such as chemical production and hydrogen generation. It can also be utilized for enhanced oil recovery, where the injection of CBM into oil reservoirs can help to increase oil production.